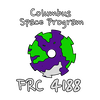

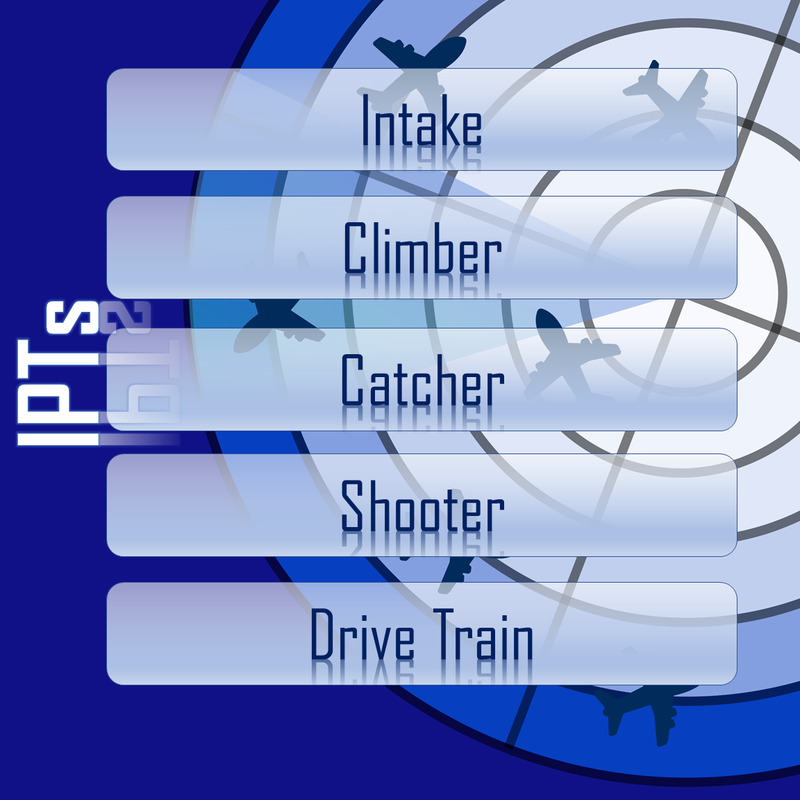

Columbus Space Program has implemented programs in support of our build facility, our team, and our robots. We adjusted our development process in 2017 to an agile spiral development systems engineering process -- allowing for completing and improvement over a season.

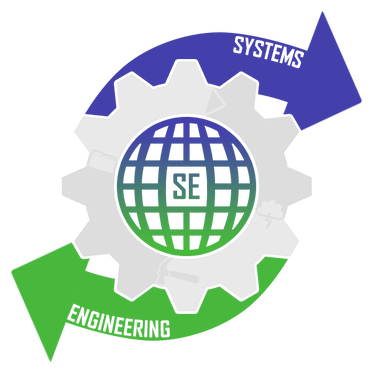

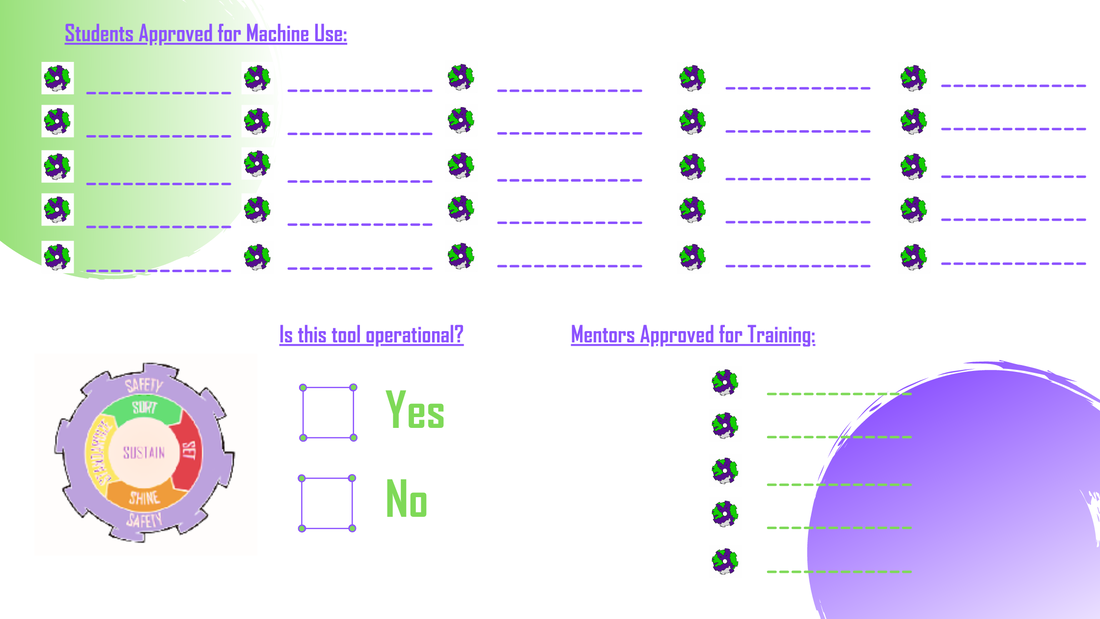

5S - At a Glance

5S Logo est. 2016

5S Logo est. 2016

SORT : Sort out and remove unnecessary items

SET : Arrange and identify necessary items in a neat and logical order for ease of access

SHINE : Clean regularly, remove dust, trash and unnecessary items, check what has been changed

STANDARDIZE : Standardize the process and repeat good practices

SUSTAIN : Self-discipline to understand and maintain the standards and continuously improve

and let''s not forget the most important part of 5S : SAFETY!

History of 5S in CSP

Buildsite before 5S

Buildsite before 5S

5S was implemented within CSP's facility in 2016, with the purpose of providing a safer work environment for our students and mentors. Our 5S lead was inspired by ONEDA, one of our sponsors, and decided that it would be beneficial for CSP to implement it to our CSP.

During the first few trials of applying the newly found knowledge, many students were apprehensive about the capabilities of 5S. It was after a few weeks with the encouragements of one of our mentors from ONEDA when we managed to attain the 5S program for ourselves- and it did bring a change to our facility and workspace.

During the first few trials of applying the newly found knowledge, many students were apprehensive about the capabilities of 5S. It was after a few weeks with the encouragements of one of our mentors from ONEDA when we managed to attain the 5S program for ourselves- and it did bring a change to our facility and workspace.

CSP started by starting with the the basics- the main steps that were arguably the most important part of 5S. Taking out the trash more often, organizing materials after every build session, and making sure that safety glasses were worn at all times were a few methods that CSP carried out to gradually absorb 5S, During the summer and pre-season days, we would often have 5S-days in which we would spend the entire day to clean, vacuum, label, and organize all aspects of the Columbus Robotics Facility, from the gym (where our field is) to the machine room to the restrooms to even the programming section!

Buildsite after 5S

Buildsite after 5S

CSP is currently still going through the process of maintaining our facility 5S-ed. We

acknowledge that it's a tough, ongoing development skill that makes us efficient, which is why we

want to spread the recognition for the need of 5S.

CSP is currently still going through the process of maintaining our facility 5S-ed. We

acknowledge that it's a tough, ongoing development skill that makes us efficient, which is why we

want to spread the recognition for the need of 5S.

Upcoming Events

With the COVID pandemic, this sharing program has been put on hold. Our 5S lead is looking into virtual opportunities to share our program with others.